WFC22-A

Product Introduction

Traditional injection mold design is mainly two-dimensional and empirical design. It is difficult to express the shape and structure of the product correctly and in detail by using two-dimensional engineering drawings alone, and it cannot be directly applied to CNC machining. The analysis and calculation cycle in the design process is long , with poor accuracy. With the development of CAD/CAE/CAM technology, the modern injection mold design method is that the designer directly builds the 3D model of the product on the computer, carries out the mold structure design and optimization design according to the product 3D model, and then performs NC according to the 3D model of the mold structure design. programming.

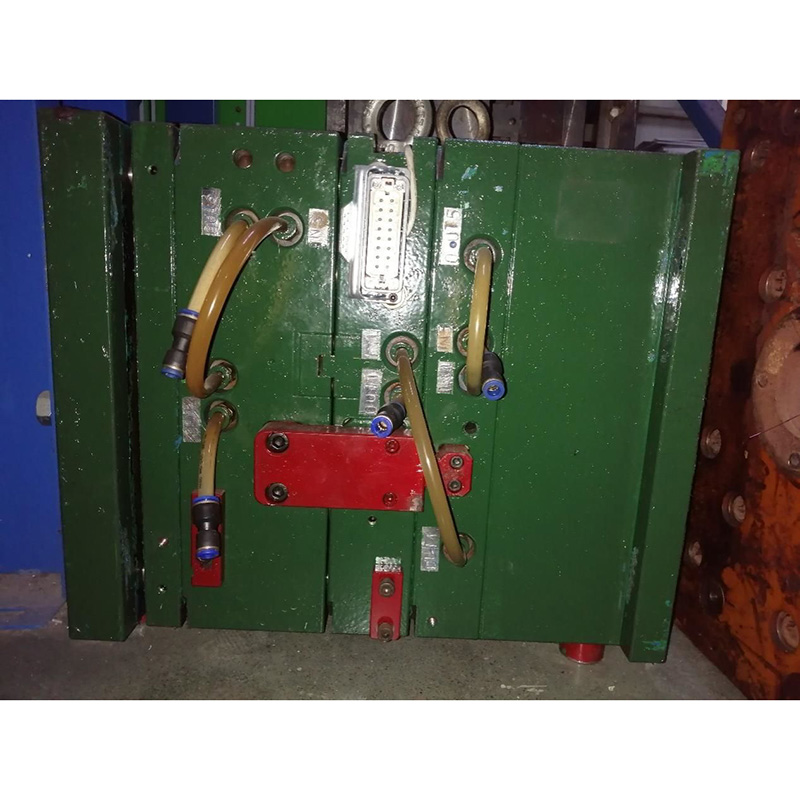

This is a mold made by our factory for customers and is being used. It is one of the new molds that will start to be used in November 2022.

We have professional mold production and processing equipment and teams. The molds we manufacture are all strictly in accordance with the requirements. Dimensionally stable products made with our molds.

The production steps of the mold mainly include drawing review - material preparation - processing - mold base processing - mold core processing - electrode processing - mold parts processing - inspection - assembly - flying mold - test mold - -Production.

A professional mold design team analyzes your products to maximize the utilization of product materials. Scientifically reduce the loss of the mold during the course of use, maintain the mold in time, improve the service life of the mold, and reduce the maintenance cost and maintenance cycle. Design easy-to-use molds, scientific and reasonable demoulding methods, shorten production cycle time, and improve product production efficiency.