Introduction to Mold Products

Product Description

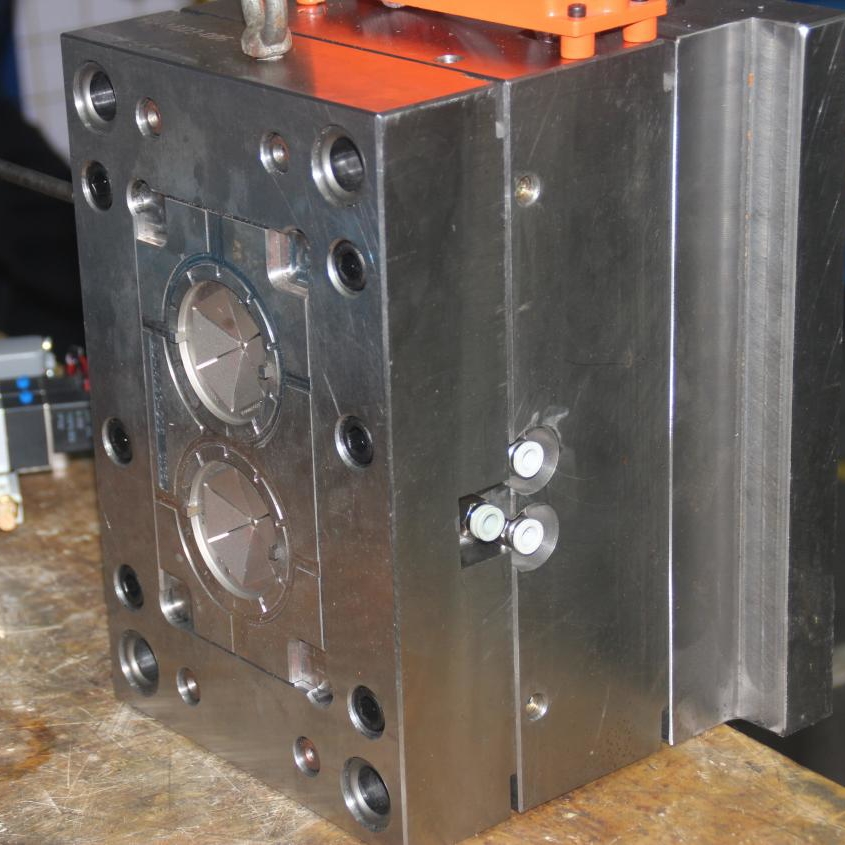

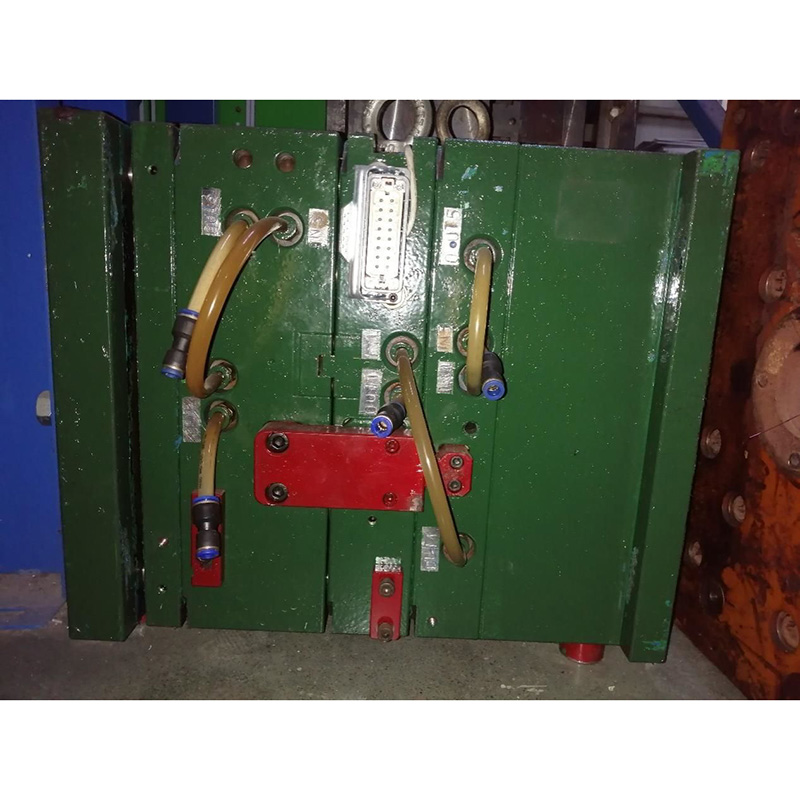

The production process of molds involves several stages, including mold design, mold making, and mold finishing. First, mold designers create a 3D CAD model of the mold based on the specifications of the final product. Next, mold makers use CNC machines to manufacture the mold, which involves cutting and shaping metal pieces to create the final mold. Finally, the mold is finished by polishing and coating it to ensure a smooth surface.

Machines Used in the Production Process

To manufacture molds, several machines are required, including CNC milling machines, EDM machines, and wire cutting machines. These machines use computer-controlled tools to cut, shape, and finish the mold components with precision and accuracy.

Materials Used to Make Molds

The materials used to make molds are critical to their performance and durability. The most commonly used materials for mold making include steel, aluminum, and copper alloys. The selection of the material depends on factors such as the production volume, the complexity of the product, and the required surface finish.

Determining Mold Quality

The quality of a mold can be determined by several factors, including its accuracy, durability, and surface finish. A well-designed and well-made mold should produce products with precise dimensions, minimal flash, and no defects. The mold should also be durable enough to withstand the repeated stress of the injection molding process.

Our Services

We offer comprehensive mold design and manufacturing services, including CAD modeling, mold making, and 3D printing. Our team of experts uses the latest technology and techniques to ensure that our molds meet the highest standards of quality and performance. Additionally, we provide technical support and maintenance services to ensure that our customers can achieve optimal performance from their molds.

Conclusion

Molds are a critical component in plastic injection molding, and their quality and performance can significantly impact the final product. By using the latest technology and techniques, we can provide high-quality