Sheet Metal Fabrication

-

Baiyear custom made emergency electronic box Centralized power supply for emergency lighting Special for fire emergency lamps enclosure

According to the drawings, requirements, and ideas provided by customers, we provide metal cutting and bending services to help customers with sheet metal parts processing. Our automated cutting process guarantees high precision and high quality of the finished part. All parts can be sprayed, heat treated and other post-processing according to customer requirements.

You can choose from a variety of different metal sheets with varying strength, conductivity, weight, and corrosion resistance.

Basic Principles of Laser Cutting.

CNC laser cutting is a computer-controlled machining process that uses a high-density beam of light to cut parts from sheet metal workpieces. This process is done under the guidance of a computer according to a pre-uploaded 2D model. The laser cutting process is known for its cost-effectiveness and high precision.

-

Baiyear Factory OEM Stainless Steel Waterproof metal box IP66 Emergency lighting centralized power controller Box

Electrical equipment enclosure electronic cabinets distribution control metal box

Welcome your design, we accept customization

Material Stainless Steel/Metal/Aluminum/Galvanized/Cold plate Thickness Depends on your products. Lock Galvanized, chrome-plated, custom-made. Screw Metal,stainless steel and accept custom. Process Spot welding, joint polishing, etc. Specification Customized,or according to your drawing. Protection level Accept customized, such as IP65 IP 66, IP67,IP68. Customized Accept OEM/ODM. Surface finish Zine plating/Electroplating/Powder coating Manfacturing Service Laser cutting/Shearing/Punching/Bending/Welding/Coating/Others Products application scope Electric,Industry,Construction… -

Specializing in the production of various metal boxes, high-quality sheet metal processing manufacturers

This product is only a customer case product display, not for sale, and for reference only.

Sheet metal products are widely used in various industries due to their excellent mechanical properties, low cost, and ease of manufacturing. In this introduction, we will provide an overview of our sheet metal production process, including the machines we use, the materials we choose, how to evaluate the quality of sheet metal, and the services we provide.

-

Sheet metal fabrication factory for Precision sheet metal Custom sheet metal Sheet metal forming

This product is only a customer case product display, not for sale, and for reference only.

Welcome to our official website, where we provide you with a comprehensive introduction to our sheet metal products. Here is what you need to know about our sheet metal products:

-

Stainless steel fabrication and Precision metal fabrication with CNC metal fabrication Metal finishing Powder coating Sandblasting

This product is only a customer case product display, not for sale, and for reference only.

Welcome to our sheet metal fabrication page. We are dedicated to providing high-quality sheet metal products to meet your unique needs. Here’s a brief introduction to our sheet metal production process, the machines we use, our material selection process, and how we ensure the quality of our products.

-

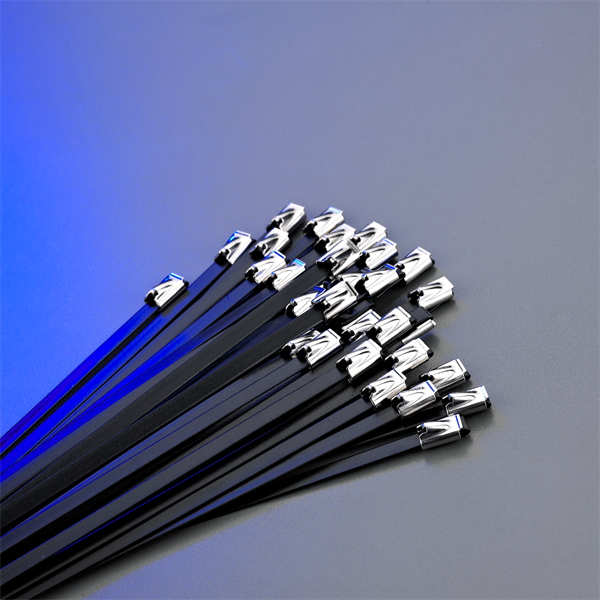

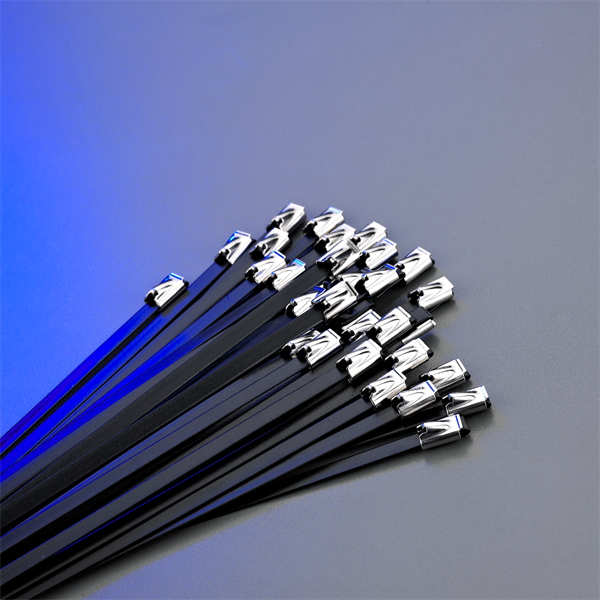

Plastic Coated Stainless Steel Zip Ties

Technical Parameters List Stainless steel tie most uses 201 304 stainless steel and coated with PVC cover, coated stainless steel cable tie product will be insulated from Acids, alkalis, salts, oxidation. To protect the cable tie coated for longer time use. PVC cover color, black and other colors are available. Material: ASTM304 Size: Width5.5*Length100,150,200,250,300,350,400,450,500,550,600,650,700,750,800,850,900,950,1000,1100,1200,1300,1400,1500 Width9*Length100,130,150,200,250,300,350,40... -

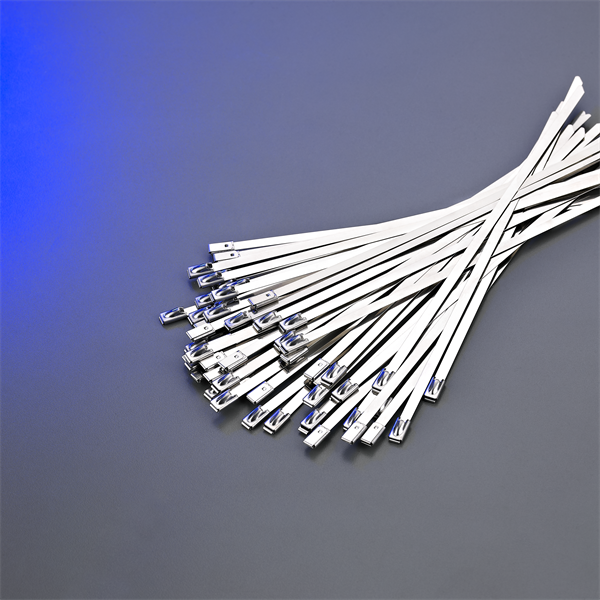

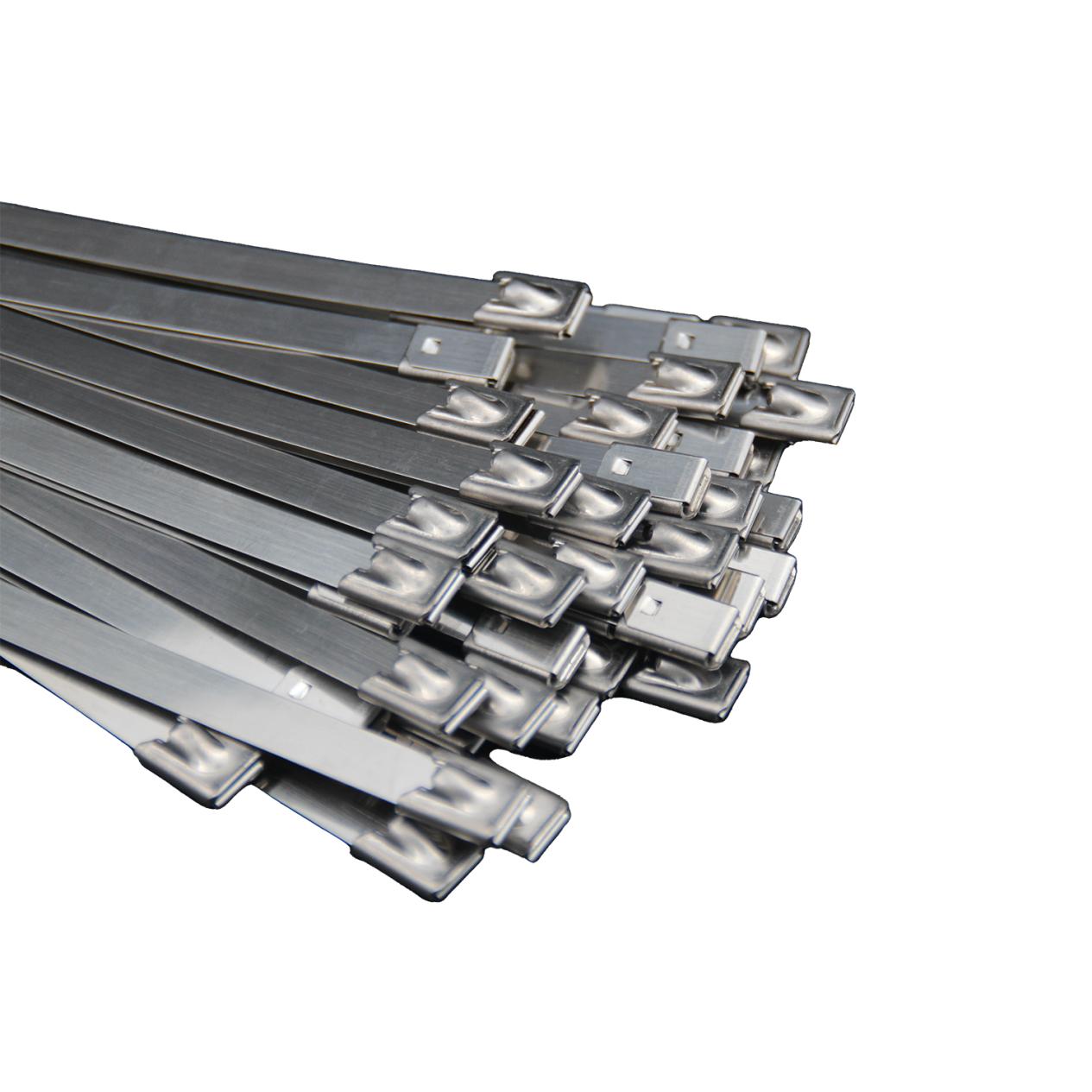

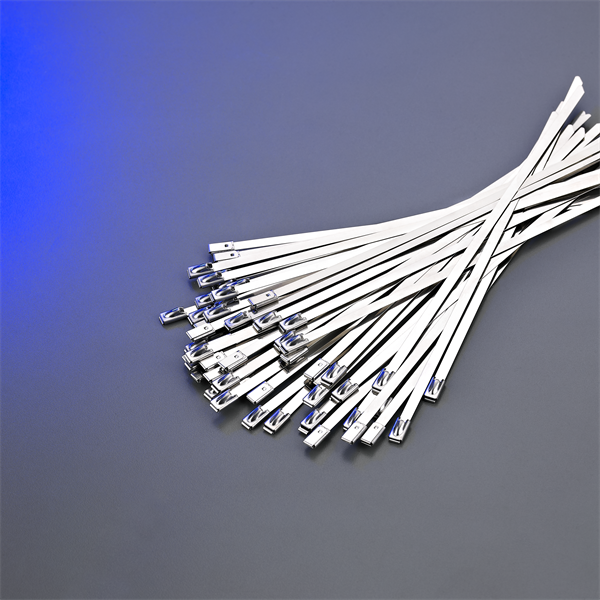

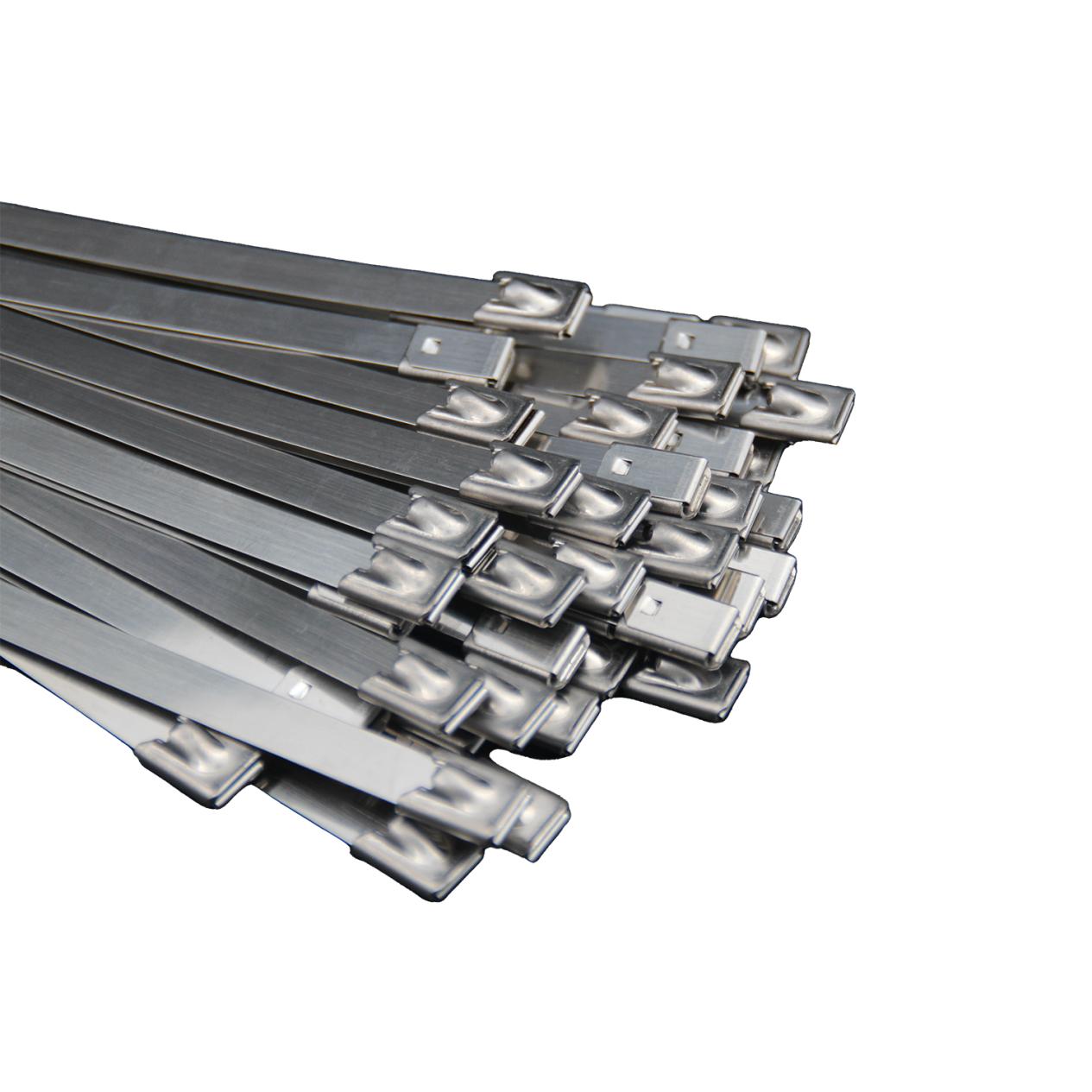

Stainless Steel Zip Ties

Technical Parameters List Metal zip ties are one kind zip tie design for well work in extreme temperatures and severe environmental conditions. And metal wire cable ties offer tensile strength bundling and securing a wide assortment of cable, wires, and assemblies. Metal material is stainless steel; metal cable zip ties different level stainless steel are used in different applications that require corrosion-resistant. Material: ASTM304 Size: Thickness mm Width mm Length mm 0.25 ... -

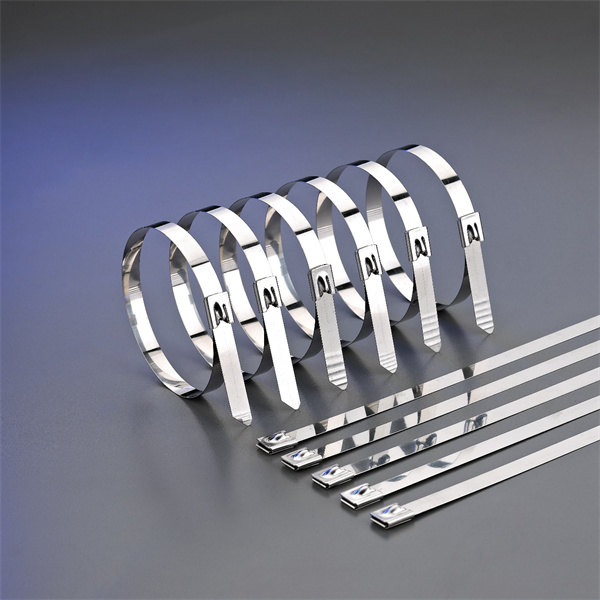

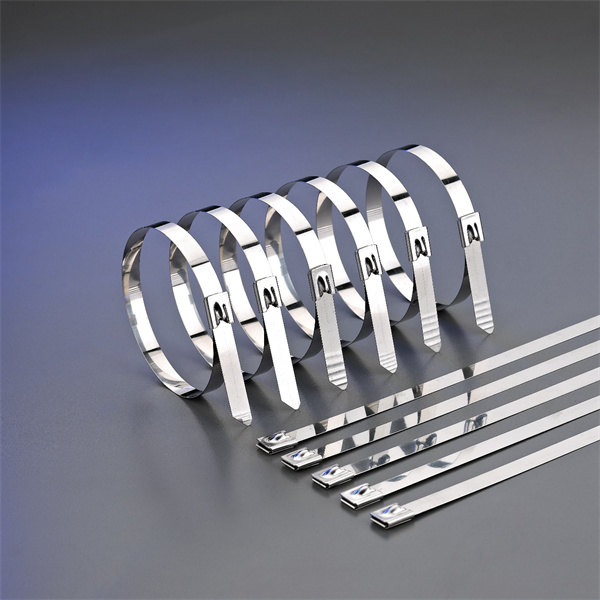

Stainless Steel Zip Ties

Technical Parameters List Stainless steel cable ties are used to fix multiple electronic cables or wires to the photovoltaic system. The cable tie is made of corrosion-resistant stainless steel, which is suitable for harsh corrosion conditions and provides a strong and durable method for cable binding. The stainless-steel cable tie has a unique self-locking mechanism. Material: ASTM304 Size: Thickness mm Width mm Length mm 0.25 4.6 100 150 200 250 300 350 400 450 500 550 600 6... -

Self-Locking PVC Coated 304 Stainless Steel Ties with High Temperature Resistance – Pack of 100

Material: ASTM304

Size: 11.8” *0.18” *0.01”

Quantity: 100 PCS

-

Heavy-Duty Stainless Steel Zip Ties (100 PCS) – ASTM304, 0.18’’x11.8’’

Material: ASTM304

Size: 0.18’’x11.8’’

Quantity: 100 PCS

Introducing our Heavy-Duty Stainless Steel Zip Ties – the perfect solution for organizing and securing cables, wires, hoses, and other objects that need to be tied together. Made from high-quality ASTM304 stainless steel, these zip ties are durable, corrosion-resistant, and able to withstand extreme temperatures and weather conditions. With a size of 0.18’’x11.8’’, they offer a versatile and reliable solution for a wide range of applications.

-

Heavy-Duty Stainless Steel Zip Ties – 100 Pack 0.3”x11.8” for Indoor and Outdoor Use

Material: ASTM304

Size: 0.3’’x11.8’’

Quantity: 100 PCS

-

Baiyear Metal Electrical Box Enclosure Outdoor waterproof electrical box control power distribution enclosure electric metal box

This product is only a customer case product display, not for sale, and for reference only.

An electrical enclosure is used to protect users from electric shock and electrical or electronic components from the environment. The manufacturers of the electrical enclosure not only concentrate on the safety aspect of it, but also on the attractiveness, to make the enclosure pleasing to the eye. The electrical enclosure can be used to mount switches, displays and knobs. Metals, plastics, stainless steel, carbon steel and aluminum are the materials used to manufacture the electrical enclosure. Customized electrical enclosure can be used for mass-produced equipment and on the other hand, standardized enclosure is used for low production equipment. Electrical enclosure is also used to protect electrical equipment such as transmitters, power distribution systems, power generators, etc.