ODM Best Injection Molding Custom Plastic Injection Mold Factories - Customer product example of Baiyear injection molding processing fire fighting supplies: JBF6131-D input interface module – Baiyear

ODM Best Injection Molding Custom Plastic Injection Mold Factories - Customer product example of Baiyear injection molding processing fire fighting supplies: JBF6131-D input interface module – Baiyear Detail:

Technical parameter list

| content | technical parameter |

| loopback bus | Modulation type, two bus lines, no polarity |

| monitor current | ≤0.25mA DC24V |

| Encoding | Electronic Encoder Coding |

| Coding range | 1-252 |

| input indicator | Monitoring status: The “input action” light is flashing red. Fault status: The “input action” light flashes red twice continuously. Feedback status: The “input action” light is red and bright. |

| Dimensions | 85mm × 85mm× 41mm length × width × height |

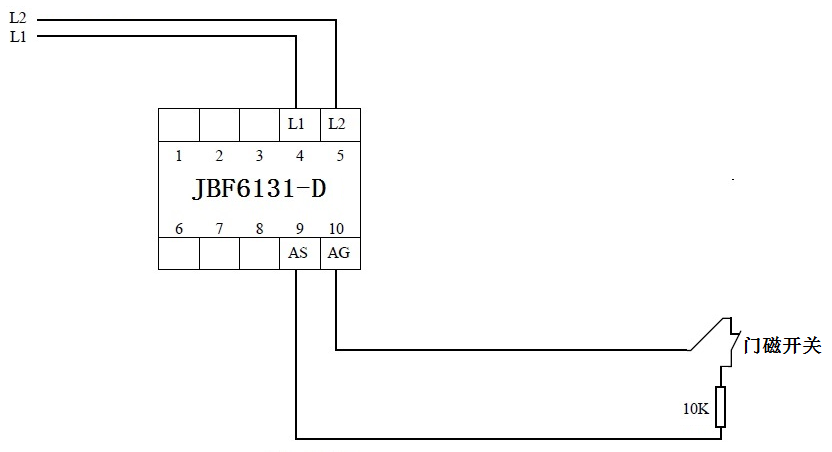

Wiring Instructions

L1 (terminal 4) and L2 (terminal 5) are connected to the loop bus without polarity;

AS (terminal 9), AG (terminal 10 is connected to the door magnetic switch (passive contact);

The moving and disconnecting ends of the door magnetic switch connected to the AS and AG terminals of the input interface module must be used in series with a 10KΩ terminal resistor;

Application Notes

The input interface module is mainly used to monitor the normally closed fire door, receive the action signal of the door magnetic switch, to judge whether the normally closed fire door operates, and upload the information to the fire door monitor for display and alarm. The module should be installed near the fire door, and each fire door is equipped with a JBF6131-D input interface module.

How we control product quality

Baiyear has strict quality control standards and quality management system

“Quality is the lifeblood of an enterprise” is the basic working principle of our quality department.

Quality Prevention

The factory has set up a quality prevention team whose main job responsibilities are: if our quality control is not controlled from the source, it will be difficult for us to control the quality of our products. This requires us to do a good job in the first time to prevent the occurrence of quality problems.

Incoming quality inspection

After the material requirement order is placed, the enterprise conducts acceptance inspection on the products supplied by the supplier

Process inspection

When the product is launched, it is required to confirm the quality of the first piece of the product. The function of the production test is to confirm the first piece and to conduct quality specification and supervision in the batch production process.

Principles of Product Quality Control

Set production standards

Before the company manufactures, a detailed production standard is determined, which will include production activity standards and supervision of inspection.

Whoever produces is in charge

The producer of the product is also the person in charge of the quality of the product, and the production staff must make the product according to the production standard of the product. For the unqualified products produced, the production personnel should take the initiative to deal with them, find out the reasons for the unqualified products, and make adjustments in time. Can’t leave the problem to someone else.

Who produces who inspects

The producer of the product is also the inspector of the product quality, and the self-inspection of the product quality is just a reconfirmation of whether the produced product is qualified. Through re-confirmation, unqualified products are prevented from flowing into the next link, and at the same time, the problems that may exist in the production process are found to be improved in time. Continuously improve their operating skills and improve product quality.

Full inspection

Our products must be fully inspected before leaving the factory to ensure the pass rate of our products.

In-process inspection

The quality of the product is produced, and the production staff in this process will be more familiar with our products than others. Arranging the production personnel in this process to conduct self-inspection can find out the quality problems of the products more easily and faster. At the same time, it can also improve the production staff’s sense of responsibility for product quality in this process. Conducive to the self-improvement of product quality in this process.

Bad discontinuation

In the production process, once it is found that unqualified products are continuously produced, the operator will stop processing.

Process it now

In the production process, any non-conforming products should be dealt with immediately.

Bad products are exposed

Analyze the causes of product failure together, and make adjustments to product standards or management processes. Let everyone understand product quality problems together. Only in this way can the operator reflect on what problems may exist in his operation during the production process, to avoid the occurrence of these problems, and how to deal with these problems when they occur again. Rather than simply rework or scrap the substandard products, otherwise, such problems will continue.

Supervised check

It is necessary to supervise and inspect other personnel other than the producer himself, and strictly control the key links to reduce the occurrence of quality problems.

Management support

The company has formulated a reasonable production management system. When unqualified products occur, the management system will assess producer and assume certain responsibilities, so as to motivate producer to carry out production work carefully.

You just need to provide your design ideas, we can help you realize it!

Product detail pictures:

Related Product Guide:

Our mission will be to grow to be an innovative supplier of high-tech digital and communication devices by giving worth added design and style, world-class production, and service capabilities for ODM Best Injection Molding Custom Plastic Injection Mold Factories - Customer product example of Baiyear injection molding processing fire fighting supplies: JBF6131-D input interface module – Baiyear , The product will supply to all over the world, such as: Cape Town, Paraguay, Benin, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Just give them the drawings and they'll take care of everything and give you the perfect quote.