Introduction:

In the world of manufacturing, the design and production of plastic parts play a vital role in numerous industries. Behind the scenes, there is an art and science at work known as plastic part mold design and manufacturing. This captivating field combines creativity, engineering prowess, and precision to create functional and aesthetically appealing plastic components. In this article, we will delve into the fascinating world of plastic part mold design and manufacturing, exploring the key aspects that make it both alluring and essential in today’s industrial landscape

The Intersection of Design and Engineering:

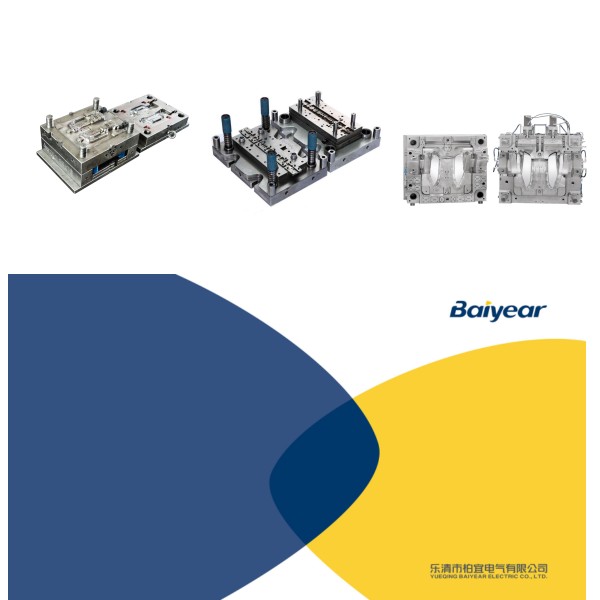

Plastic part mold design is an intriguing blend of artistic vision and engineering expertise. Designers harness their creativity to conceptualize the shape, structure, and appearance of the plastic part. They carefully consider factors such as functionality, ergonomics, and market appeal. Simultaneously, engineers employ their technical knowledge to transform these designs into manufacturable molds, optimizing factors like mold flow, cooling systems, and ejection mechanisms. This harmonious collaboration between design and engineering sets the stage for the creation of exceptional plastic parts.

Precision Engineering for Flawless Production:

In the realm of plastic part manufacturing, precision is paramount. Mold manufacturing involves the meticulous craftsmanship of creating molds that will produce flawless plastic parts. Highly skilled technicians employ advanced techniques, such as computer-aided design (CAD), computer numerical control (CNC) machining, and electrical discharge machining (EDM), to fabricate molds with utmost accuracy. The convergence of cutting-edge technology and masterful craftsmanship ensures that each mold is a work of art, capable of delivering consistent and high-quality plastic parts.

The Role of Innovation in Mold Design:

Innovation is the lifeblood of plastic part mold design. With the rapid advancement of technology, designers and engineers are continually pushing the boundaries of what is possible. They explore new materials, experiment with novel mold construction techniques, and leverage simulation tools for mold flow analysis. Innovation drives the development of molds that enable complex geometries, enhanced part functionality, and improved production efficiency. The pursuit of innovation in mold design fosters a competitive edge and empowers industries to meet evolving consumer demands.

Quality Control and Product Validation:

The journey of a plastic part from design to production involves rigorous quality control and product validation processes. Advanced inspection techniques, such as coordinate measuring machines (CMM) and 3D scanning, ensure that the manufactured plastic parts adhere to precise dimensional specifications. Additionally, functional testing and validation procedures assess factors such as strength, durability, and compatibility. These stringent quality control measures guarantee that the final plastic parts meet or exceed industry standards, providing confidence in their performance and reliability.

Sustainability in Plastic Part Mold Design:

In recent years, sustainability has emerged as a critical consideration in plastic part mold design and manufacturing. Designers and engineers are actively exploring eco-friendly materials, optimizing manufacturing processes for minimal waste, and incorporating recyclability into the design of plastic parts. The focus on sustainability not only reduces environmental impact but also enhances brand reputation and aligns with the growing demand for environmentally conscious products.

Conclusion:

Plastic part mold design and manufacturing is a captivating field that combines artistic vision, engineering excellence, and technological innovation. The seamless integration of design and engineering, the precision in mold manufacturing, the pursuit of innovation, and the commitment to quality control contribute to the allure and importance of this discipline. As industries continue to evolve and consumer expectations rise, plastic part mold design and manufacturing will remain at the forefront of unlocking innovation and shaping the future of manufacturing.

Post time: Jun-25-2023