By Andy from Baiyear factory

Upated November 1, 2022

Sheet metal has not yet had a relatively complete definition. According to a definition in a foreign professional journal, it can be defined as: Sheet metal is a comprehensive cold working process for thin metal plates (usually below 6mm), including shearing, punching /cutting/compounding, folding, welding, riveting, splicing, forming (such as car body), etc. Its remarkable feature is that the thickness of the same part is the same.

Sheet metal cutting is an important process for forming sheet metal products. It includes traditional cutting, blanking, bending forming and other methods and process parameters, as well as various cold stamping die structures and process parameters, various equipment working principles and operating methods, as well as new stamping technology and new technology .

For any sheet metal part, it has a certain processing process, which is the so-called technological process. With the difference in the structure of sheet metal parts, the technological process may be different, but the total does not exceed the following points.

1. Design and draw the part drawing of its sheet metal parts, also known as three views. Its function is to express the structure of its sheet metal parts by means of drawings.

2. Draw an unfolded diagram. That is, unfold a part with a complex structure into a flat part.

3. Blanking. There are many ways of blanking, mainly in the following ways:

a. Shearing machine cutting. It is to use a shearing machine to cut out the shape, length and width of the expanded drawing. If there are punching and corner cutting, then turn the punching machine to combine the die punching and corner cutting to form.

b. Punch blanking. It is to use the punch to punch the flat part structure after the parts are unfolded on the plate in one or more steps. It has the advantages of short man-hours, high efficiency, and can reduce processing costs.

c. NC CNC blanking. When NC blanking, the first step is to write the CNC machining program. It is to use the programming software to write the drawn expansion diagram into a program that can be recognized by the NC CNC machining machine. Let it follow these programs step by step on an iron plate On, punch out the structural shape of its flat parts.

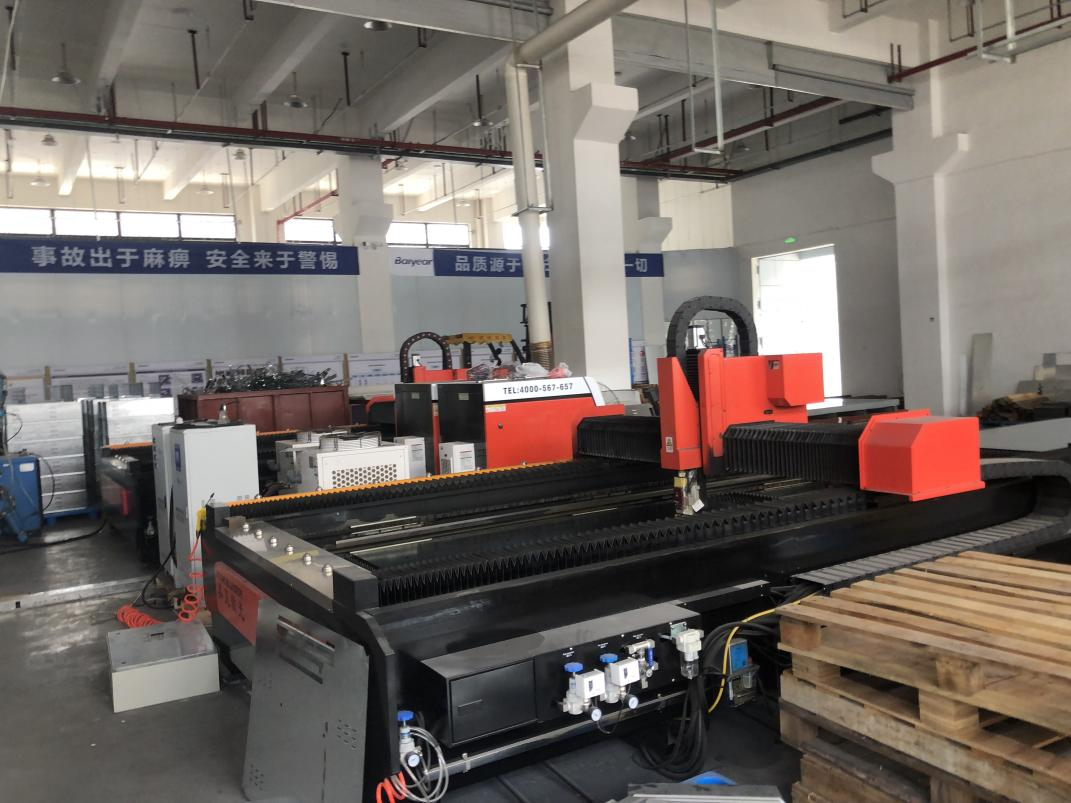

d. Laser cutting. It uses the laser cutting method to cut the structural shape of its flat parts on an iron plate.

4. Flanging and tapping. Flanging is also called hole drilling, which is to draw a slightly larger hole on a smaller base hole, and then tap the hole. This can increase its strength and avoid slippage. Generally used for sheet metal processing with relatively thin plate thickness. When the plate thickness is large, such as plate thickness above 2.0, 2.5, etc., we can tap directly without flanging.

5. Punch processing. Generally, punching and corner cutting, punching blanking, punching convex hull, punching and tearing, punching and other processing methods are used to achieve the processing purpose. The processing requires corresponding molds to complete the operation. There are convex hull molds for punching convex hulls, and tear forming molds for punching and tearing.

6. Pressure riveting. As far as our factory is concerned, pressure riveting studs, pressure riveting nuts, pressure riveting screws, etc. are often used. Riveted to sheet metal parts.

7. Bending. Bending is to fold 2D flat parts into 3D parts. Its processing requires a bending machine and a corresponding bending die to complete the operation. It also has a certain bending sequence. The first fold that does not interfere will produce the latter fold that interferes.

8. Welding. Welding is to weld multiple parts together to achieve the purpose of processing or to weld the side seam of a single part to increase its strength. The processing methods generally include the following: CO2 gas shielded welding, argon arc welding, Spot welding, robot welding, etc. The selection of these welding methods is based on actual requirements and materials. Generally speaking, CO2 gas shielded welding is used for iron plate welding; argon arc welding is used for aluminum plate welding; robot welding is mainly used in material It is used when the parts are large and the welding seam is long. Such as cabinet welding, robot welding can be used, which can save a lot of tasks and improve work efficiency and welding quality.

9. Surface treatment. Surface treatment generally includes phosphating film, electroplating multicolored zinc, chromate, baking paint, oxidation, etc. Phosphating film is generally used for cold-rolled sheets and electrolytic sheets, and its function is mainly to coat the surface of the material. A protective film is applied to prevent oxidation; the second is to enhance the adhesion of its baking paint. Electroplating colorful zinc is generally used for surface treatment of cold-rolled plates; chromate and oxidation are generally used for surface treatment of aluminum plates and aluminum profiles; its specific surface The choice of processing method is determined according to the customer’s requirements.

10. Assembly. The so-called assembly is to assemble multiple parts or components together in a certain way to make them a complete item. One of the things to pay attention to is the protection of the material, not scratches and bumps. Assembly is the last step in the completion of a material. If the material cannot be used due to scratches and bumps, it needs to be reworked and reworked, which will waste a lot of processing time and increase The cost of the item. Therefore, special attention should be paid to the protection of the item.

Post time: Nov-29-2022